Fermented Soy Powder

Fermented Soy Powder Product Introduction

Fermented Soy Powder Product Introduction

Product Overview

Fermented Soy Powder is a nutrient-rich food ingredient derived from soybeans through a natural fermentation process. This innovative product combines traditional fermentation techniques with modern food science to enhance digestibility, bioavailability, and flavor profile. The fermentation process breaks down complex proteins and carbohydrates into simpler forms, making it easier for the body to absorb essential nutrients. Fermented Soy Powder is widely used in dietary supplements, functional foods, and bakery products due to its high protein content, probiotic benefits, and umami taste.

Key Features

• Enhanced Nutrition: Fermentation increases amino acid availability and reduces anti-nutritional factors.

• Probiotic Benefits: Contains live beneficial bacteria supporting gut health.

• Versatile Application: Ideal for protein bars, smoothies, soups, and plant-based meat alternatives.

• Clean Label: Free from artificial additives, non-GMO, and allergen-friendly

Ingredients

|

Parameter |

Standard Value |

| Product Name | Fermented Soy Powder |

| Moisture | ≤13% |

| Iron (Fe) | ≤10 ppm |

| Lead (Pb) | ≤1 ppm |

| Protein Content | ≥40% (dry basis) |

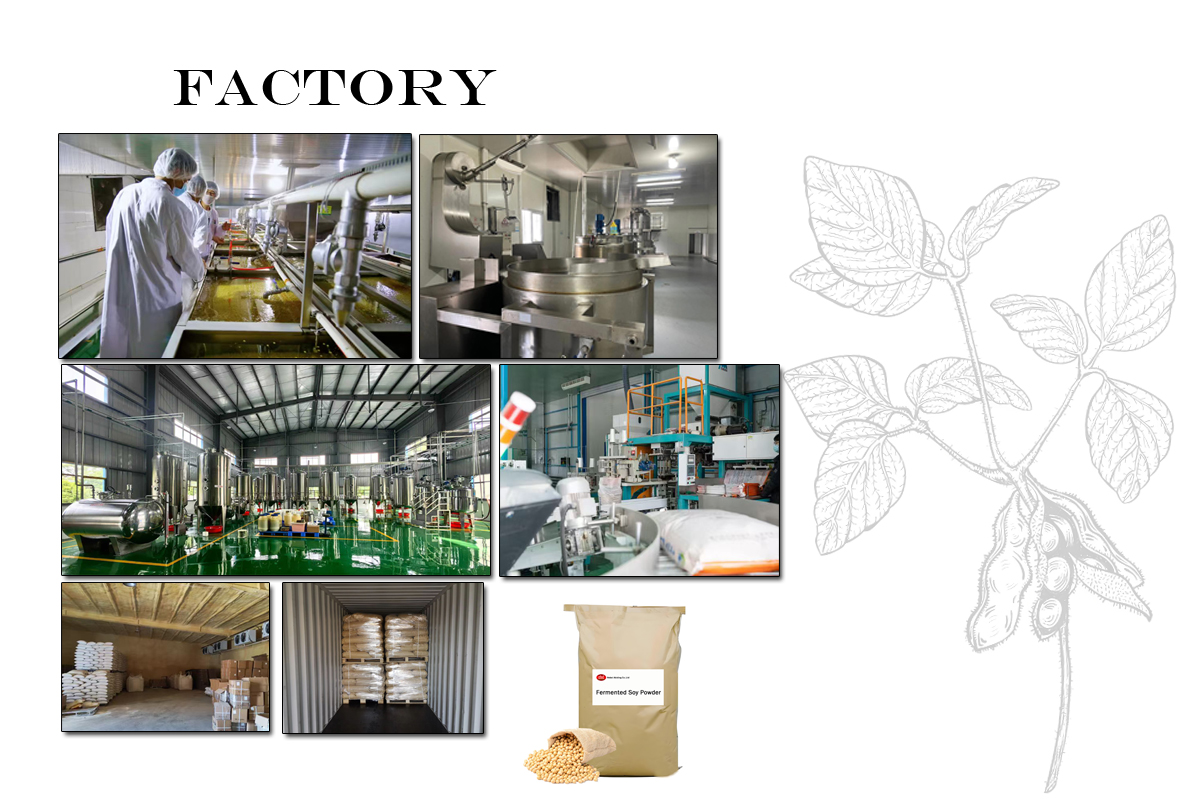

Production Process

RAW MATERIAL SORTING

• Non-GMO soybeans are selected, cleaned, and sorted to remove impurities.

• Quality control includes moisture and foreign matter inspection.

STEAMING

• Soybeans undergo steam treatment at 121°C for 15–20 minutes to gelatinize starch and denature proteins.

• Ensures complete inactivation of natural enzymes and pathogens.

FERMENTATION

• Inoculated with proprietary probiotic strains (e.g., Bacillus subtilis).

• Fermented at 40–45°C for 48–72 hours in controlled humidity (RH 85–90%).

• Regular mixing ensures uniform microbial activity.

DRY & RIPENING

• Fermented material is dried at 60–65°C to reduce moisture to ≤13%.

• Post-drying aging (24–48 hours) enhances flavor development.

GRINDING

• Dried product is milled into fine powder (80–100 mesh).

• Sieving ensures consistent particle size for smooth application.

Quality Assurance

• HACCP & ISO 22000: Complies with international food safety standards.

• Heavy Metal Control: ICP-MS analysis for Fe, Pb, and other contaminants.

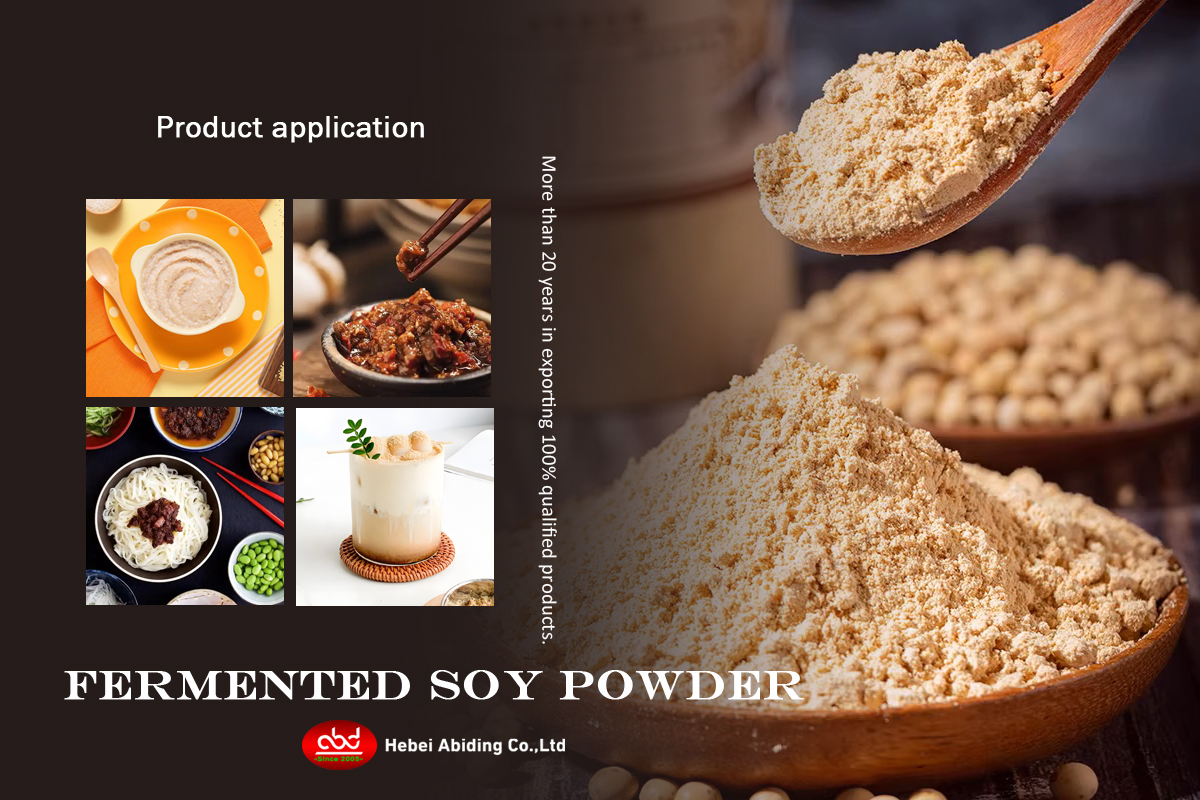

Applications

Nutritional Supplements: Added to protein shakes and meal replacements.

Bakery & Confectionery: Enhances texture and flavor in breads and cookies.

Animal Feed: Used as a protein source in aquaculture and poultry diets (with adjusted specifications).

Packaging & Storage

Multi-layer bags (25kg/bag).

Store in cool, dry conditions (<25°C, RH <60%) to preserve quality.

Why Choose Our Product?

Consistent Quality: Strict adherence to specifications ensures batch-to-batch uniformity.

Sustainability: Zero-waste production process; byproducts repurposed for animal feed.

Customization: Available in organic or fortified variants (e.g., with added vitamins).

For detailed technical data or samples, contact our sales team.